Prysmian group, a global leader in fiber optic products, wanted to increase rentability in their warehousing space using real-time inventory indicators and wanted visibility on their stocking and shipping orders. We helped Prysmian achieve their goals with a solution that uses handheld devices to track products and shipments this reducing shipping and storage times. Company Impact The time to prepare shipping items was reduced by 58%, from 2 hours to 50 minutes on average. In addition, the company has now a set planning tools that allow for continuous improvement and goal setting.

“With the tools developed by Sitek for managing the inventory and shipments we were able to handle thousands of movements in a controlled and efficient way”

For Essilor, a manufacturer of high quality lenses, we implemented an intelligent pattern recognition system to classify final products to their corresponding packaging area. Errors in packaging a serious quality assurance problem for the company and with this system they reached the goals defined.

“The tools developed by Sitek help us increases our productivity andreduce errors with smart and innovative solutions”

For Essilor, a manufacturer of high quality lenses, we developed a group of Enterprise dashboards to increase yield and show the productivity KPIs while measuring the usage time of equipment.

Essilor had tried to hit a goal of 98% line utilization without success.After the delivery of the productivity KPI dashboard in one of the lines, it was able to reach the 98% utilizationgoal and maintain it for the following 6 months.

“We work with Sitek generating several reports and tools that help us reduce significantly hours of labor and provide us with valuable information for the operation and decision making”

For Prysmian group, a global leader in cable products for energy and data, we were given the challenge to redesign their production control system that as used in 3 different locations around the world.

We took the existing platform and modernize it to state-of-the-art technologies.

With these improvements, the plant quickly became the most productive plant in the world, achieving a yield target of 98% in 2018, superior in 2% compared with other similar plants of the organization.

“Sitek worked with us in an ambitious project to re-engineering our MES system an several other systems of the plant that work with it. After several months of work, now we have a brand new system with state of the art technology and with optimized process and operation, persisting the data of our legacy system and without operation brakes”

American Industries is one of the largest operators of industrial Parks in Mexico and the US. Sitek integrated their Oracle-based supplier system with a government tax payment system. With this automated process, human intervention is only required for exception handling.

American Industries would perform a manual supplier validation that required 3 full-time employees 5 days a month to validate 3700 suppliers.

This was reduced to one person reviewing

We work with Sitek on several areas of our organization, mostly maintaining a set of heterogeneous systems (internal and external) with different technologies and making them work together

Prysmian group, a global leader in fiber optic products, wanted to increase rentability in their warehousing space using real-time inventory indicators and wanted visibility on their stocking and shipping orders. We helped Prysmian achieve their goals with a solution that uses handheld devices to track products and shipments this reducing shipping and storage times.

Company Impact

The time to prepare shipping items was reduced by 58%, from 2 hours to 50 minutes on average. In addition, the company has now a set planning tools that allow for continuous improvement and goal setting.

“With the tools developed by Sitek for managing the inventory and shipments we were able to handle thousands of movements in a controlled and efficient way”

For Essilor, a manufacturer of high quality lenses, we implemented an intelligent pattern recognition system to classify final products to their corresponding packaging area. Errors in packaging a serious quality assurance problem for the company and with this system they reached the goals defined.

“The tools developed by Sitek help us increases our productivity andreduce errors with smart and innovative solutions”

For Essilor, a manufacturer of high quality lenses, we developed a group of Enterprise dashboards to increase yield and show the productivity KPIs while measuring the usage time of equipment.

Essilor had tried to hit a goal of 98% line utilization without success.After the delivery of the productivity KPI dashboard in one of the lines, it was able to reach the 98% utilizationgoal and maintain it for the following 6 months.

“We work with Sitek generating several reports and tools that help us reduce significantly hours of labor and provide us with valuable information for the operation and decision making”

For Prysmian group, a global leader in cable products for energy and data, we were given the challenge to redesign their production control system that as used in 3 different locations around the world.

We took the existing platform and modernize it to state-of-the-art technologies.

With these improvements, the plant quickly became the most productive plant in the world, achieving a yield target of 98% in 2018, superior in 2% compared with other similar plants of the organization.

“Sitek worked with us in an ambitious project to re-engineering our MES system an several other systems of the plant that work with it. After several months of work, now we have a brand new system with state of the art technology and with optimized process and operation, persisting the data of our legacy system and without operation brakes”

American Industries is one of the largest operators of industrial Parks in Mexico and the US. Sitek integrated their Oracle-based supplier system with a government tax payment system. With this automated process, human intervention is only required for exception handling.

American Industries would perform a manual supplier validation that required 3 full-time employees 5 days a month to validate 3700 suppliers.

This was reduced to one person reviewing

We work with Sitek on several areas of our organization, mostly maintaining a set of heterogeneous systems (internal and external) with different technologies and making them work together

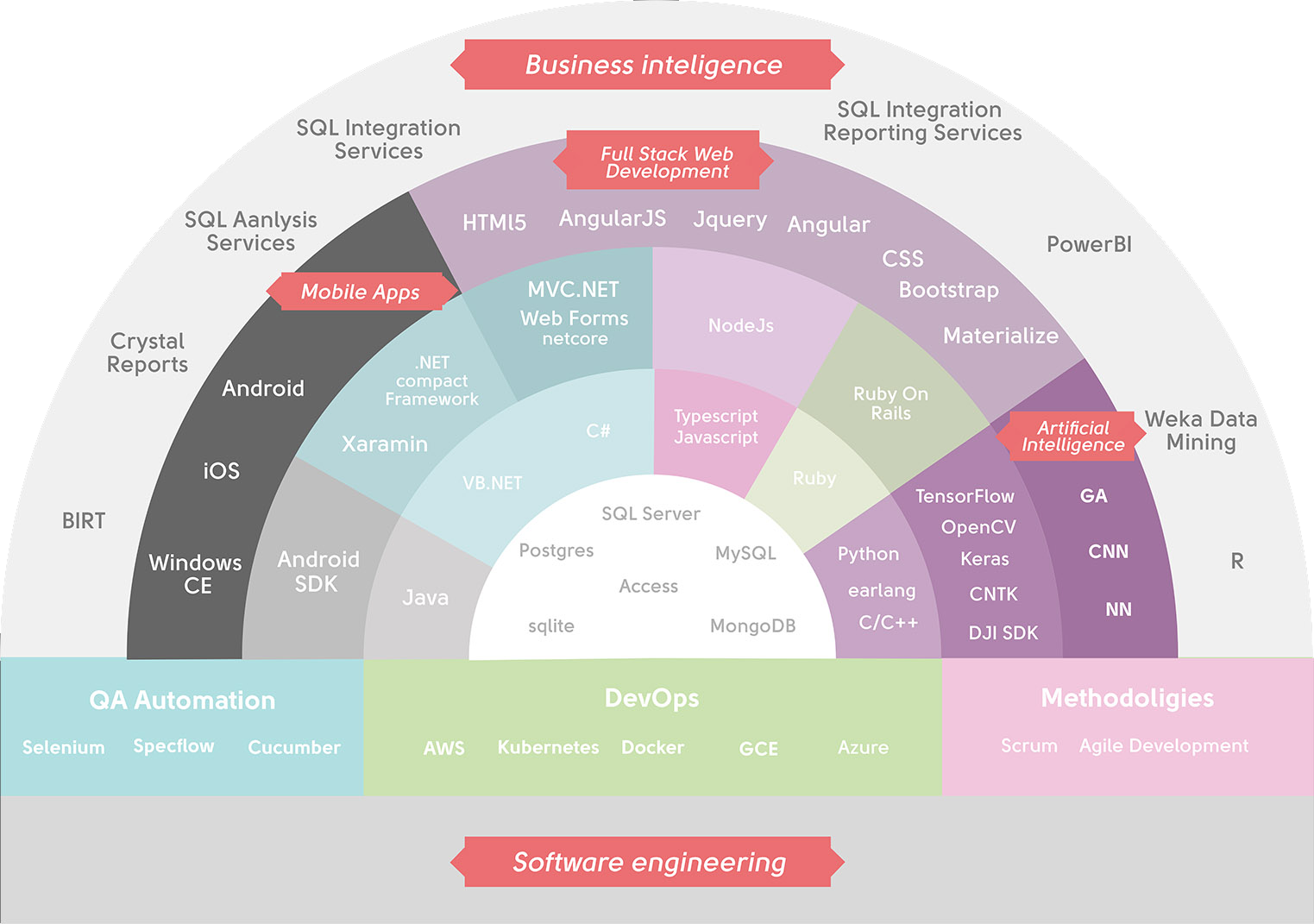

To ensure the quality of our services, Sitek has a competent team of engineers with specialized skills in the Industry 4.0 technologies. We have many years of experience delivering small and large scale projects for the manufacturing industry, especially with automotive and logistic companies. We like challenges, our customers reach out to us because of the quality of our work and our ability to solve difficult problems.